A few nice Weight loss images I found:

Aerobithon – U.S. Army Garrison Humphreys, South Korea – 19 May 2012

Image by USAG-Humphreys

Click here to learn more about Camp Humphreys

U.S. Army photos by Rakendra Moore

Camp Humphreys hosts aerobithon

By Rakendra Moore

USAG Humphreys Public Affairs

CAMP HUMPHREYS — An aerobithon was held at the Super Gym May 19, with participants dancing, spinning, and jumping their way to better fitness.

“It was great,” said Elvia Palumbo, one of the Zumba instructors for the event. “This was a great way to introduce all of the classes offered in the Super Gym.”

The aerobithon included a warm-up session, followed by Zumba, a stationary bicycle workout and yoga.

“We worked the total body,” said Karen Morton, who organized the aerobithon. “Exercising like this helps you feel better about yourself.”

Morton once weighed 260 pounds, but turned her life around with regular workouts and can now say, “I think I look good for my age.”

Blair Bogle, who also participated in last year’s aerobithon, likewise praised the virtues of diet and exercise.

“Living a healthy life is an everyday thing,” she said.

“I think the energy is high and people are into taking care of their body for a lifetime,” Morton added. “This is a lifestyle for me.”

Also participating was the husband-wife team of Peter and Christi Herring, who have lost a total of 73 pounds this year.

“This was meant for younger people,” Mrs. Herring said with a laugh. “But I like it.”

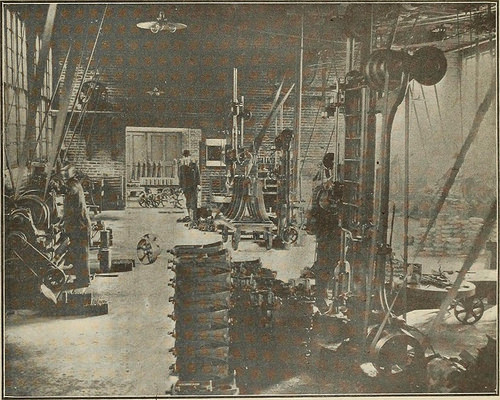

Image from page 112 of “Canadian machinery and metalworking (January-June 1913)” (1913)

Image by Internet Archive Book Images

Identifier: canmachinerjanjun1913toro

Title: Canadian machinery and metalworking (January-June 1913)

Year: 1913 (1910s)

Authors:

Subjects: Machinery Machinery Machinery

Publisher: Toronto MacLean-Hunter

Contributing Library: Fisher – University of Toronto

Digitizing Sponsor: Algoma University, Trent University, Lakehead University, Laurentian University, Nipissing University, Ryerson University and University of Toronto Libraries

View Book Page: Book Viewer

About This Book: Catalog Entry

View All Images: All Images From Book

Click here to view book online to see this illustration in context in a browseable online version of this book.

Text Appearing Before Image:

g handling to a minimum.These bins are shown on the plan, ashort distance to the north of the foun-dry. The Dodge Co.s method of mouldinglarge rope sheaves, large belt pulleys,etc., is of considerable interest. Insteadof sweeping up the rim in loam or green outside rim segments are placed. Thehub is then completed, all joints aremade good with clay and a wide castiron ring, somewhat larger in diameterthan the mould, is dropped over the lat-ter and green sand rammed around thedry sand cores, as clearly shown in thecut. This method has proved highlysatisfactory, the loss of a casting beingan extremely rare occurrence. Castings up to 11 tons in weight arefrequently made in this foundry and thetotal output averages 85 tons per week.Belt pulleys from 26 in. to 48 in. indiameter are made on stripping platepulley moulding machines and the out-put of the light foundry is nearly allmachine work. It consists chiefly ofstandard parts, sue!) as hangers. Con-veyor stands, small hangers and similar

Text Appearing After Image:

FIG. 10. A SECTION OF THE HANGER SHOP sand and making the hub and arms indry sand, as is the common practice,they always mould the outside face ofthe rim in dry sand and frequently theinside face also. Fig. 9 shows how thisis accomplished in the case of a ropepulley, the rim and part of one arm only-being shown. The rim is moulded in drysand segments, each segment being madein a core box. Very large or wide pul-leys are moulded in a pit, but those ofmoderate size merely have the floor lev-elled off and a flat core plate, to buildup the hub cores upon, bedded into thefloor. A circle is then marked out on thefloor and the rim core segments are setto this. In the case of a six-armedwheel, six of the inner core segmentsare provided with an inlet for the armcore. The latter is inserted before the castings are made on Pridmore dropplate machines, and there is a Pridmorestripping plate machine which is usuallybusy on 6-in. pulleys. A man canmould 170 of these pulleys on it per dayof nine hou

Note About Images

Please note that these images are extracted from scanned page images that may have been digitally enhanced for readability – coloration and appearance of these illustrations may not perfectly resemble the original work.

Green dress

Image by Queenie & the Dew

Blogged: www.queenieandthedew.com/2013/07/what-i-wore-and-6-week-w…