A few nice Weight loss images I found:

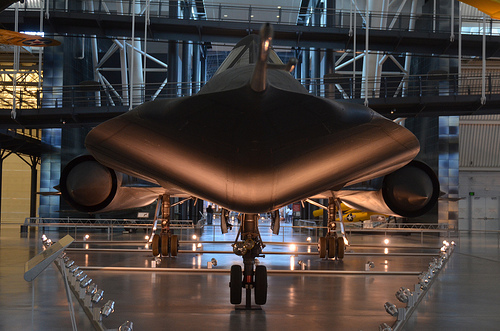

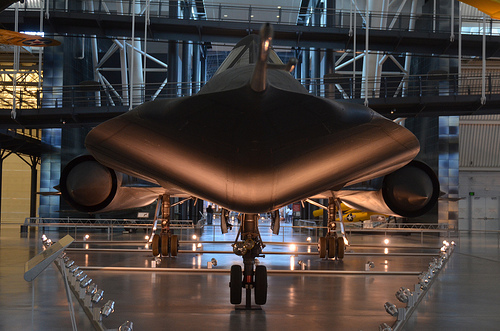

Steven F. Udvar-Hazy Center: SR-71 Blackbird (nose view)

Image by Chris Devers

See more photos of this, and the Wikipedia article.

Details, quoting from Smithsonian National Air and Space Museum | Lockheed SR-71 Blackbird:

No reconnaissance aircraft in history has operated globally in more hostile airspace or with such complete impunity than the SR-71, the world’s fastest jet-propelled aircraft. The Blackbird’s performance and operational achievements placed it at the pinnacle of aviation technology developments during the Cold War.

This Blackbird accrued about 2,800 hours of flight time during 24 years of active service with the U.S. Air Force. On its last flight, March 6, 1990, Lt. Col. Ed Yielding and Lt. Col. Joseph Vida set a speed record by flying from Los Angeles to Washington, D.C., in 1 hour, 4 minutes, and 20 seconds, averaging 3,418 kilometers (2,124 miles) per hour. At the flight’s conclusion, they landed at Washington-Dulles International Airport and turned the airplane over to the Smithsonian.

Transferred from the United States Air Force.

Manufacturer:

Lockheed Aircraft Corporation

Designer:

Clarence L. "Kelly" Johnson

Date:

1964

Country of Origin:

United States of America

Dimensions:

Overall: 18ft 5 15/16in. x 55ft 7in. x 107ft 5in., 169998.5lb. (5.638m x 16.942m x 32.741m, 77110.8kg)

Other: 18ft 5 15/16in. x 107ft 5in. x 55ft 7in. (5.638m x 32.741m x 16.942m)

Materials:

Titanium

Physical Description:

Twin-engine, two-seat, supersonic strategic reconnaissance aircraft; airframe constructed largley of titanium and its alloys; vertical tail fins are constructed of a composite (laminated plastic-type material) to reduce radar cross-section; Pratt and Whitney J58 (JT11D-20B) turbojet engines feature large inlet shock cones.

Long Description:

No reconnaissance aircraft in history has operated in more hostile airspace or with such complete impunity than the SR-71 Blackbird. It is the fastest aircraft propelled by air-breathing engines. The Blackbird’s performance and operational achievements placed it at the pinnacle of aviation technology developments during the Cold War. The airplane was conceived when tensions with communist Eastern Europe reached levels approaching a full-blown crisis in the mid-1950s. U.S. military commanders desperately needed accurate assessments of Soviet worldwide military deployments, particularly near the Iron Curtain. Lockheed Aircraft Corporation’s subsonic U-2 (see NASM collection) reconnaissance aircraft was an able platform but the U. S. Air Force recognized that this relatively slow aircraft was already vulnerable to Soviet interceptors. They also understood that the rapid development of surface-to-air missile systems could put U-2 pilots at grave risk. The danger proved reality when a U-2 was shot down by a surface to air missile over the Soviet Union in 1960.

Lockheed’s first proposal for a new high speed, high altitude, reconnaissance aircraft, to be capable of avoiding interceptors and missiles, centered on a design propelled by liquid hydrogen. This proved to be impracticable because of considerable fuel consumption. Lockheed then reconfigured the design for conventional fuels. This was feasible and the Central Intelligence Agency (CIA), already flying the Lockheed U-2, issued a production contract for an aircraft designated the A-12. Lockheed’s clandestine ‘Skunk Works’ division (headed by the gifted design engineer Clarence L. "Kelly" Johnson) designed the A-12 to cruise at Mach 3.2 and fly well above 18,288 m (60,000 feet). To meet these challenging requirements, Lockheed engineers overcame many daunting technical challenges. Flying more than three times the speed of sound generates 316° C (600° F) temperatures on external aircraft surfaces, which are enough to melt conventional aluminum airframes. The design team chose to make the jet’s external skin of titanium alloy to which shielded the internal aluminum airframe. Two conventional, but very powerful, afterburning turbine engines propelled this remarkable aircraft. These power plants had to operate across a huge speed envelope in flight, from a takeoff speed of 334 kph (207 mph) to more than 3,540 kph (2,200 mph). To prevent supersonic shock waves from moving inside the engine intake causing flameouts, Johnson’s team had to design a complex air intake and bypass system for the engines.

Skunk Works engineers also optimized the A-12 cross-section design to exhibit a low radar profile. Lockheed hoped to achieve this by carefully shaping the airframe to reflect as little transmitted radar energy (radio waves) as possible, and by application of special paint designed to absorb, rather than reflect, those waves. This treatment became one of the first applications of stealth technology, but it never completely met the design goals.

Test pilot Lou Schalk flew the single-seat A-12 on April 24, 1962, after he became airborne accidentally during high-speed taxi trials. The airplane showed great promise but it needed considerable technical refinement before the CIA could fly the first operational sortie on May 31, 1967 – a surveillance flight over North Vietnam. A-12s, flown by CIA pilots, operated as part of the Air Force’s 1129th Special Activities Squadron under the "Oxcart" program. While Lockheed continued to refine the A-12, the U. S. Air Force ordered an interceptor version of the aircraft designated the YF-12A. The Skunk Works, however, proposed a "specific mission" version configured to conduct post-nuclear strike reconnaissance. This system evolved into the USAF’s familiar SR-71.

Lockheed built fifteen A-12s, including a special two-seat trainer version. Two A-12s were modified to carry a special reconnaissance drone, designated D-21. The modified A-12s were redesignated M-21s. These were designed to take off with the D-21 drone, powered by a Marquart ramjet engine mounted on a pylon between the rudders. The M-21 then hauled the drone aloft and launched it at speeds high enough to ignite the drone’s ramjet motor. Lockheed also built three YF-12As but this type never went into production. Two of the YF-12As crashed during testing. Only one survives and is on display at the USAF Museum in Dayton, Ohio. The aft section of one of the "written off" YF-12As which was later used along with an SR-71A static test airframe to manufacture the sole SR-71C trainer. One SR-71 was lent to NASA and designated YF-12C. Including the SR-71C and two SR-71B pilot trainers, Lockheed constructed thirty-two Blackbirds. The first SR-71 flew on December 22, 1964. Because of extreme operational costs, military strategists decided that the more capable USAF SR-71s should replace the CIA’s A-12s. These were retired in 1968 after only one year of operational missions, mostly over southeast Asia. The Air Force’s 1st Strategic Reconnaissance Squadron (part of the 9th Strategic Reconnaissance Wing) took over the missions, flying the SR-71 beginning in the spring of 1968.

After the Air Force began to operate the SR-71, it acquired the official name Blackbird– for the special black paint that covered the airplane. This paint was formulated to absorb radar signals, to radiate some of the tremendous airframe heat generated by air friction, and to camouflage the aircraft against the dark sky at high altitudes.

Experience gained from the A-12 program convinced the Air Force that flying the SR-71 safely required two crew members, a pilot and a Reconnaissance Systems Officer (RSO). The RSO operated with the wide array of monitoring and defensive systems installed on the airplane. This equipment included a sophisticated Electronic Counter Measures (ECM) system that could jam most acquisition and targeting radar. In addition to an array of advanced, high-resolution cameras, the aircraft could also carry equipment designed to record the strength, frequency, and wavelength of signals emitted by communications and sensor devices such as radar. The SR-71 was designed to fly deep into hostile territory, avoiding interception with its tremendous speed and high altitude. It could operate safely at a maximum speed of Mach 3.3 at an altitude more than sixteen miles, or 25,908 m (85,000 ft), above the earth. The crew had to wear pressure suits similar to those worn by astronauts. These suits were required to protect the crew in the event of sudden cabin pressure loss while at operating altitudes.

To climb and cruise at supersonic speeds, the Blackbird’s Pratt & Whitney J-58 engines were designed to operate continuously in afterburner. While this would appear to dictate high fuel flows, the Blackbird actually achieved its best "gas mileage," in terms of air nautical miles per pound of fuel burned, during the Mach 3+ cruise. A typical Blackbird reconnaissance flight might require several aerial refueling operations from an airborne tanker. Each time the SR-71 refueled, the crew had to descend to the tanker’s altitude, usually about 6,000 m to 9,000 m (20,000 to 30,000 ft), and slow the airplane to subsonic speeds. As velocity decreased, so did frictional heat. This cooling effect caused the aircraft’s skin panels to shrink considerably, and those covering the fuel tanks contracted so much that fuel leaked, forming a distinctive vapor trail as the tanker topped off the Blackbird. As soon as the tanks were filled, the jet’s crew disconnected from the tanker, relit the afterburners, and again climbed to high altitude.

Air Force pilots flew the SR-71 from Kadena AB, Japan, throughout its operational career but other bases hosted Blackbird operations, too. The 9th SRW occasionally deployed from Beale AFB, California, to other locations to carryout operational missions. Cuban missions were flown directly from Beale. The SR-71 did not begin to operate in Europe until 1974, and then only temporarily. In 1982, when the U.S. Air Force based two aircraft at Royal Air Force Base Mildenhall to fly monitoring mission in Eastern Europe.

When the SR-71 became operational, orbiting reconnaissance satellites had already replaced manned aircraft to gather intelligence from sites deep within Soviet territory. Satellites could not cover every geopolitical hotspot so the Blackbird remained a vital tool for global intelligence gathering. On many occasions, pilots and RSOs flying the SR-71 provided information that proved vital in formulating successful U. S. foreign policy. Blackbird crews provided important intelligence about the 1973 Yom Kippur War, the Israeli invasion of Lebanon and its aftermath, and pre- and post-strike imagery of the 1986 raid conducted by American air forces on Libya. In 1987, Kadena-based SR-71 crews flew a number of missions over the Persian Gulf, revealing Iranian Silkworm missile batteries that threatened commercial shipping and American escort vessels.

As the performance of space-based surveillance systems grew, along with the effectiveness of ground-based air defense networks, the Air Force started to lose enthusiasm for the expensive program and the 9th SRW ceased SR-71 operations in January 1990. Despite protests by military leaders, Congress revived the program in 1995. Continued wrangling over operating budgets, however, soon led to final termination. The National Aeronautics and Space Administration retained two SR-71As and the one SR-71B for high-speed research projects and flew these airplanes until 1999.

On March 6, 1990, the service career of one Lockheed SR-71A Blackbird ended with a record-setting flight. This special airplane bore Air Force serial number 64-17972. Lt. Col. Ed Yeilding and his RSO, Lieutenant Colonel Joseph Vida, flew this aircraft from Los Angeles to Washington D.C. in 1 hour, 4 minutes, and 20 seconds, averaging a speed of 3,418 kph (2,124 mph). At the conclusion of the flight, ‘972 landed at Dulles International Airport and taxied into the custody of the Smithsonian’s National Air and Space Museum. At that time, Lt. Col. Vida had logged 1,392.7 hours of flight time in Blackbirds, more than that of any other crewman.

This particular SR-71 was also flown by Tom Alison, a former National Air and Space Museum’s Chief of Collections Management. Flying with Detachment 1 at Kadena Air Force Base, Okinawa, Alison logged more than a dozen ‘972 operational sorties. The aircraft spent twenty-four years in active Air Force service and accrued a total of 2,801.1 hours of flight time.

Wingspan: 55’7"

Length: 107’5"

Height: 18’6"

Weight: 170,000 Lbs

Reference and Further Reading:

Crickmore, Paul F. Lockheed SR-71: The Secret Missions Exposed. Oxford: Osprey Publishing, 1996.

Francillon, Rene J. Lockheed Aircraft Since 1913. Annapolis, Md.: Naval Institute Press, 1987.

Johnson, Clarence L. Kelly: More Than My Share of It All. Washington D.C.: Smithsonian Institution Press, 1985.

Miller, Jay. Lockheed Martin’s Skunk Works. Leicester, U.K.: Midland Counties Publishing Ltd., 1995.

Lockheed SR-71 Blackbird curatorial file, Aeronautics Division, National Air and Space Museum.

DAD, 11-11-01

Citroen 7 CV

Image by pedrosimoes7

Oeiras, Portugal

in Wikipedia

Traction Avant monocoque

Front torsion bar suspension

The Traction Avant, French for "front wheel drive", was designed by André Lefèbvre and Flaminio Bertoni in late 1933 / early 1934. While not the first production front wheel drive car – Alvis built the 1928 FWD in the UK, Cord produced the L29 from 1929 to 1932 in the United States and DKW the F1 in 1931 in Germany – it was the world’s first front-wheel drive steel monocoque production car. Along with DKW’s 1930s models, the Traction successfully pioneered front-wheel drive on the European mass car market.

The Traction Avant’s structure was a welded monocoque (unitized body). Most other cars of the era were based on a separate frame (chassis) onto which the non-structural body ("coachwork") was built. Monocoque construction (also called Unit Body or "Unibody" in the US today) results in a lighter vehicle, and is now used for virtually all car construction, although body-on-frame construction remains suitable for larger vehicles such as trucks.

This method of construction was viewed with great suspicion in many quarters, with doubts about its strength. A type of crash test was conceived, taking the form of driving the car off a cliff, to illustrate its great inherent resilience.

The novel design made the car very low-slung relative to its contemporaries – the Traction Avant always possessed a unique look, which went from appearing rakish in 1934 to familiar and somewhat old fashioned by 1955.

The suspension was very advanced for the car’s era. The front wheels were independently sprung, using a torsion bar and wishbone suspension arrangement,[3] where most contemporaries used live axle and cart-type leaf spring designs. The rear suspension was a simple steel beam axle and a Panhard rod, trailing arms and torsion bars attached to a 3-inch (76 mm) steel tube, which in turn was bolted to the monocoque.

Since it was considerably lighter than conventional designs of the era, it was capable of 100 km/h (62 mph), and consumed fuel only at the rate of 10 litres per 100 kilometres (28 mpg-imp; 24 mpg-US).

Variants

Cabriolet

Traction Avant rear

1937 7C Coupe Traction Avant

A French "familiale" 11 F 1954, 6 windows, 9 seats

Citroën 11 Commerciale 5-door

Traction Avant rears. The boot was lengthened and its volume doubled in Autumn 1952.[4] The original model, which was presented on 18 April 1934, was a small saloon with a 1,303 cc (79.5 cu in) engine. This model was called the 7A, which was succeeded in June 1934 by the 7B with a higher-power engine of 1,529 cc (93.3 cu in). The 7B in turn, was succeeded in October 1934 by the 7C with an even higher-output 1,628 cc (99.3 cu in) engine. Later models were the 11 (launched in November 1934), which had a 1,911 cc (116.6 cu in) four-cylinder engine, and the 15 (launched in 1938), with a 2,867 cc (175.0 cu in) six. The numbers refer to the French fiscal horsepower rating, or CV. The 11 was an 11 CV, but curiously the 15 was actually 16 CV. The 11 was built in two versions, the 11L ("légère", or "light"), which was the same size as the 7 CV, and the normal model 11, which had a longer wheelbase and wider track.

Citroën planned two variants that never entered production, since there was not enough funding available to develop them, except as running prototype vehicles. One was an automatic transmission-equipped model, based on the Sensaud de Lavaud automatic transmission, the other a 22 CV model with a 3.8 liter V8. The transmission (which was actually originally designed for the Citroen) was a "gearless" automatic, using the torque-converter alone to match engine revolutions to the drivetrain revolutions, much like the Dynaflow Transmission introduced later in the USA. The car was supposed to have a less spartan interior than the other Traction Avants and it was to feature Citroën’s own new V8 engine. About twenty prototypes were made, but when the project was canceled in 1935 due to Michelin’s takeover; they were probably all destroyed.[citation needed]

In addition to the 4-door body, the car was also produced as a 2-door coupé with a rumble seat, as a convertible and as an extended length Familial model with three rows of seats. There was even a hatchback-type Commerciale variant, in 1939, well ahead of its time, in which the tailgate was in two halves, the lower of which carried the spare wheel with the upper opening up to roof level. A one-piece top-hinged tailgate was introduced when the Commerciale resumed production in 1954 after being suspended during World War II.

Wartime disruption[edit]

In September 1939 France declared war on Germany and in June 1940 the German army rapidly invaded and occupied Northern France.[1] The war years were characterised by a desperate shortage of raw materials for civilian industry and of petrol,[1] but these factors were not apparent instantly. The Paris Motor Show scheduled for October 1939 was cancelled at short notice, but Citroën’s own planned announcements had involved the forthcoming 2CV model rather than any significant changes to the Traction.[1] For the Traction, the last “normal” year in terms of production levels was 1939, and 8,120 of the 2910mm wheelbase 1628cc engined 7C models were produced.[1] This tumbled to 1,133 in 1940, which was the first year when the plant suffered serious air-raid damage – on this occasion caused by a German attack – on 3 June 1940. Production of the cars was suspended in June 1941, by when a further 154 had been produced in the six-month period just ended. The 7C would continue to appear in Citroën price-lists until March 1944, but production of this smaller engined “7CV” version of the Traction was not resumed after the war.[1] For the more powerful 1911cc engined 11 B-light models, the equivalent figures were 27,473 units produced in 1939, 4,415 in 1940 and 2,032 for 1941, though for this model production in 1941 ended only in November 1941 so the figure for that year represents 11 months of production.[1]

In 1945 production restarted only slowly: the 11 B-light reappeared very little changed from the 1941 cars except that headlight surrounds were now painted rather than finished in chrome. By the end of December 1945 the year’s production had reached 1,525.[1] Currency depreciation is evident from the car’s listed price which had been 26,800 francs in January 1940, and had risen to 110,670 francs in October 1945.[1] In 1945 the car was the only model available from Citroën, and as another sign of the times, customers not able to supply their own tires were charged an additional 9,455 francs for a set of five.[1] In May 1946, presumably reflecting an easing of the war-time tire shortage, the car could at last be purchased with tires at no extra cost, but by now the overall price of an 11 B-light had risen to 121,180 francs.[1]

The 11 B-normal model, differentiated from the 11 B-light by its 3090mm wheelbase, experienced a similar drop off in volumes between 1939 and 1941, with just 341 cars produced during the first seven months of 1941.[1] After the war, a single 11 B-normal was produced in 1946, in time to be presented at the October 1946 Paris Motor Show: production built up during 1947, but during the car’s ten-year post-war period the shorter 11 B-light would, in France, continue to outsell the 11 B-normal.

Initially the French army lacked enthusiasm for the Citroën Traction, believing that it offered insufficient ground-clearance for their needs.[1] Nevertheless, by September 1939 roughly 250 had found their way into military service. With losses of cars at the frontier mounting, Citroën supplied a further 570 to the army between February and May 1940, and subsequent deliveries probably took place before military defeat intervened.[1] During the war many of the cars were reregistered with "WH…" (Wehrmacht Heer/Army command) license plates, having been requisitioned by the German Army.[1] These gave reliable service both in France and further afield, notably in Libya and Stalingrad. Tractions were also favoured by the Resistance, and as occupation gave way to Liberation they turned up all over France with FFI inscribed proudly on their doors. Less gloriously, the cars were known as favourites among gangsters such as the then infamous Pierrot le Fou, and his Traction gang.

UK built cars[edit]

Left-hand drive versions were built in Paris, in Forest, Belgium, in Copenhagen, Denmark for the Scandinavian market, and right-hand drive cars in Slough, England. The Slough version of the 11L was called the Light Fifteen and the long wheelbase 11 was called the Big Fifteen. This confusing terminology referred to the British fiscal tax rating of the time, which was higher than the French, so the 11CV engine was 15HP in England. The 15CV model was called "Big Six" in reference to its 6-cylinder engine. They were equipped with the leather seats and wooden dashboards popular in the UK, had a 12-volt electrical system and were distinguished by a different radiator grille and different bumpers. Some models also had a sliding sunroof.

A 1,911 cc (116.6 cu in) Light Fifteen tested by the British magazine The Motor in 1951 had a top speed of 72.6 mph (116.8 km/h) and could accelerate from 0–60 mph (97 km/h) in 29.7 seconds. A fuel consumption of 25.2 miles per imperial gallon (11.2 L/100 km; 21.0 mpg-US) was recorded. The test car cost GB£812 including taxes.[5]

A 2,866 cc (174.9 cu in) six-cylinder model was tested by the same magazine in 1954 and for this car the top speed found was 81.1 mph (130.5 km/h), acceleration from 0–60 mph (97 km/h) 21.2 seconds and fuel consumption 18.6 miles per imperial gallon (15.2 L/100 km; 15.5 mpg-US). The test car cost GB£1,349 including taxes.[6] Engineering[edit]

Citroën 11 CV Légère

The Traction Avant used a longitudinal, front-wheel drive layout, with the engine set well within the wheelbase, resulting in a very favourable weight distribution, aiding the car’s advanced handling characteristics. The gearbox was placed at the front of the vehicle with the engine behind it and the differential between them, a layout shared with the later Renault 4 and 16 and first generation Renault 5 but the opposite way round to many longitudinal front-wheel drive cars, such as the Saab 96 and Renault 12 and 18 and most Audi models. The gear change was set in the dashboard, with the lever protruding through a vertical, H-shaped gate.[7] Because this vertical orientation could have resulted in the car dropping out of gear when the lever was in the upper positions (i.e., second or reverse gears), the gear shift mechanism was locked when the mechanical clutch was engaged and released when the clutch pedal was depressed. The result of this layout, along with pendant pedals, umbrella-type handbrake control and front bench seats, was a very spacious interior, with a flat and unobstructed floor. The low-slung arrangement also eliminated the need for running boards to step into or out of the vehicle. These features made them ideal for use as limousines and taxi cabs, and they were quite popular among drivers and passengers alike. Until 1953, black was the only color available.

Impact on Motorsport[edit]

Another technical significance of Tranction Avant was the cast aluminium alloy transaxle, which was pioneered by Hans Ledwinka in the early 1930s for Tatra V570 used in front of the engine located in the rear, but was quite radical at the time.

As well as being a considerable part of the weight savings, the manufacturing facility for this transaxle contributed to the below mentioned financial crisis. But when John Cooper looked for a light transaxle case for Formula One rear engine revolution, Traction Avant unit was about the only candidate, as Volkswagen magnesium alloy transaxle was much smaller and lacking the space needed to house heftier gears needed for Formula One. The Traction Avant transaxle was used on Cooper T43 which won a F1 championship race as the first mid-mounted engine car to do so in 1958, and on its successors Cooper T45, T51 and T53. Cooper T51 won the GP World Championship in 1959.

Unlike the Volkswagen alloy case used by Hewland, the Traction Avant case could not be used up side down, as the input shaft height was much higher in relation to the output shaft axis so that the oil level needed to lubricate the gears would exceed the then-unreliable input shaft oil seal height if used upside down. So the engine needed to sit high above the ground with the oil sump space below, which was not needed by dry-sump racing engines. But the French transaxle was used by several racing car constructors in the late 1950s to 60’s with various levels of success.

In the case of Jack Brabham, who personally visited the ERSA foundry in Paris to discuss a possibility to strengthen the case ,[8] the transaxle became known as "ERSA Knight" with an additional spur-gear set mounted in the bellhousing spacer (engine to transaxle adapter) suggested by Ron Tauranac, named for Jack Knight who designed the modification and made the straight-cut gears. The height offset created by the spur gear set enabled the engine to sit lower, and became the reason why Cooper T53 was called the ‘Lowline’, which not only made Brabham the World Champion in 1960 but also became the precursor to the establishment of Brabham as a Formula One constructor.

Impact on Citroën[edit]

1954 six-cylinder 15CV with hydropneumatic suspension fitted to the rear wheels – in ‘high’ position

Traction Avant as modern wedding car

The development costs of the Traction Avant, combined with the redevelopment of its factory, were very high and Citroën declared bankruptcy in late 1934. The largest creditor was Michelin, who then owned Citroën from 1934 until 1976. Under Michelin, Citroën was run as a research laboratory, a test bed for their radial tires and new automotive technologies.

In 1954 Citroën’s experiments with hydropneumatic technology produced its first result, the "15H" – a variant of the 6-cylinder model 15 with a self-leveling, height-adjustable rear suspension, a field trial for the revolutionary DS released the following year.

Directly after the introduction of the Citroën ID, a simplified and more competitively priced version of the still revolutionary DS, production of the Traction Avant ended in July 1957. Over 23 years, 759,111 had been built, including 26,400 assembled in Slough in England, 31,750 assembled in Forest near Brussels and 1,823 assembled at Cologne in Germany. The total reflects the production stoppage during World War II.

The Traction Avant today[edit]

Big Fifteen sedan

In 2006, the oldest surviving 7A has production number ("coque nr") AZ 00-18, and is displayed in partly dismantled shape (engine and front wheels detached) in the Citroën Museum in Paris. The oldest running 7A is probably number AZ-00-23, which was, until 1 September 2006, in possession of a Dutch owner and is now with a Slovenian owner.

Traction Avants are fairly robust vehicles even by modern standards; however, they are prone to leaking water inside the cabin and care needs to be taken when buying one. Every few years, Traction Avant enthusiasts ship their vehicles to an exotic location for a rally. In 2002, for example, a group of over 30 Traction Avants drove from Los Angeles to New York without incident. [1]

cinnamon sticks

Image by CINNAMON VOGUE

Ultra-fine Ceylon Cinnamon by www.cinnamonvogue.com .

Soft and brittle makes it ideal for grinding into fresh powder used for desserts. Low coumarin Ceylon is much better than the common Cassia Cinnamon. The perfect Cinnamon for making mulled wine. Put a stick in your fine teas. Known as a powerful anti-oxidant. Commonly used by diabetics for blood sugar control. Also used for weight loss and belly fat reduction.